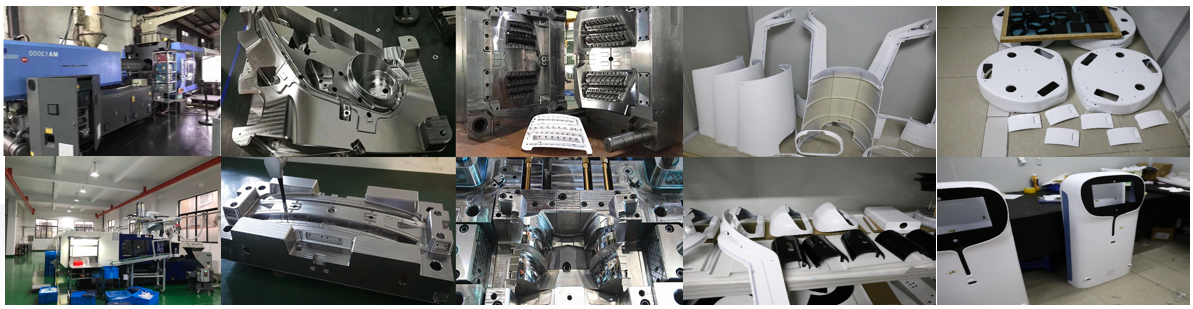

At present, most of suppliers manufacture prototypes of products mainly through 3D printing, vacuum casting, and CNC machining. With the increase of the quantity of trial production, the prototype manufacturing faces some problems such as disassembly processing affecting strength (especially for the undercuts), and differences in material composition resulting in products that cannot achieve the performance of common engineering materials. But now, we established a department speciallizing in rapid tooling for plastic injection. It has the advantages of fast lead time and low mould cost, and uses the common engineering materials on the market such as ABS, PP, POM, PA66, ABS+PC, etc. This can fully meet the performance testing and high quality prototypes of small batch trial production (less than 500 PCS). We can do the maximum product size: 1000*800mm, and the maximum tonnage of injection molding machine is 1200 Tons.